Products

- Universal Testing Machine

- Environmental Testing Chamber

- Rubber Testing Machine

- Paper Package Testing Machine

- Leather Testing Machine

- Shoes Testing Machine

- Plastic Testing Machine

- Textile Testing Machine

- Furniture Testing Machine

- Hardness Testing Machine

- Tape AdhesiveTesting Machine

- Metal Detector

- Cable/Wire Testing Machine

- Video Measuring Machine

- Baby Stroller Testing Machine

- Enameled Wire Testing Machine

- Moisture Meter

- Colorimeter

- Electronic Balance

- Battery Testing Chamber

Product Detail

Technical Parameter:

|

Model |

PTM-7017C Congo Red Thermal Stability Tester |

|

Rated voltage |

AC220V/50HZ |

|

Rated power |

800 W |

|

Temperature control range |

Room temperature ~ 300 °C, PID intelligent temperature control |

|

Temperature fluctuations |

± 0.5 °C |

|

Temperature resolution |

0.1 °C |

|

Volume |

1000 ml |

|

Timer |

0 ~ 9999h/m/s |

|

Stirring method |

magnetic stirring system |

|

Tank material |

stainless steel |

|

Test oil |

Use glycerine or 2# lubricating oil, insulating oil. (Bring your own) |

|

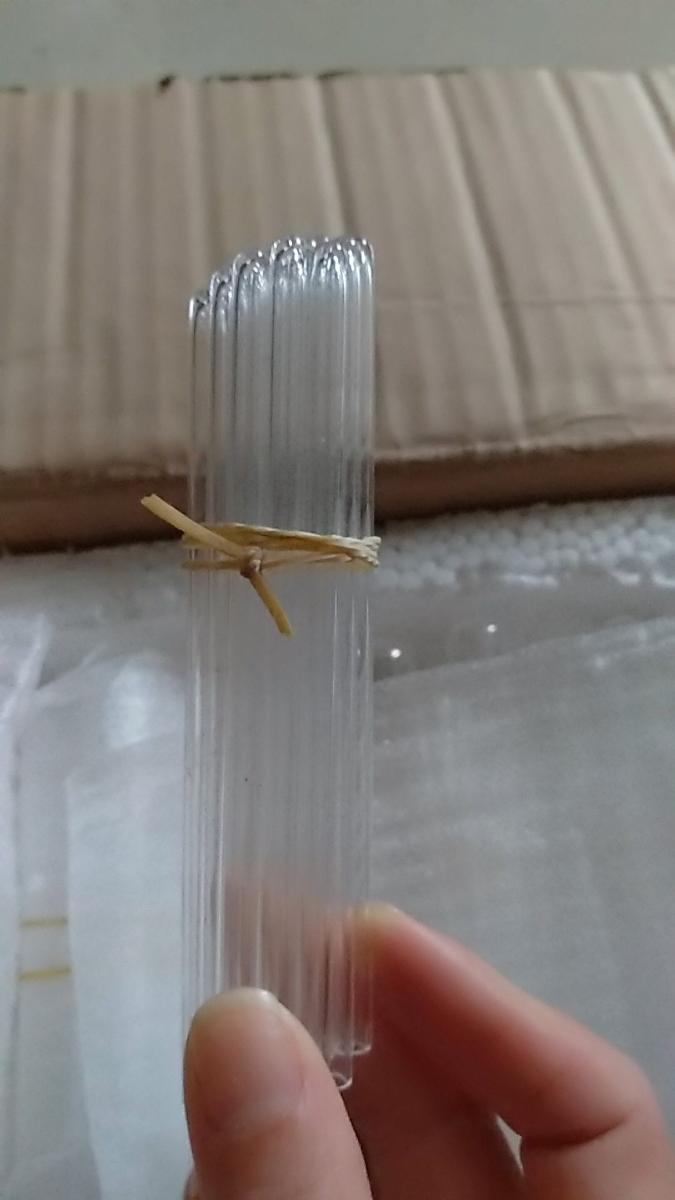

Glass tube |

GB2951 standard: length 110mm, outer diameter 5mm, inner diameter 4mm±0.5mm sealed at one end GB8815 standard: length 95mm, inner diameter 12-13mm sealed at one end |

Equipment Summary:

The structure and performance of the instrument meet the GB/T2951.32-2008 (IEC 60811-3-2:1985) and GB/T 8815-2008 "

soft PVC plastic for wire and cable" standard, instead of GB/T2951.7 -1997 standard. Applicable to cable industry with soft

polyethylene plastic insulation jacket to do the heat stability time and softening temperature two kinds of tests. The instrument

temperature control instrument uses an intelligent instrument with PID auto-tuning function, and on this basis, an artificial

optimization, making the temperature adjustment tends to the best condition. With the magnetic stirring device, the temperature

of the working medium in a 1000ml beaker can be uniformly and evenly reached 200±0.5°C with a small overshoot, and a high

quality is used to improve the anti-interference ability and adapt to the requirements of the continuous operation under the

laboratory conditions. The power filter, and the response time and fast temperature sensor, use the thermal stability tester to

fully meet the requirements of the test standard.